Uptime is the only time that matters!

SURE-thing Conveying Solutions

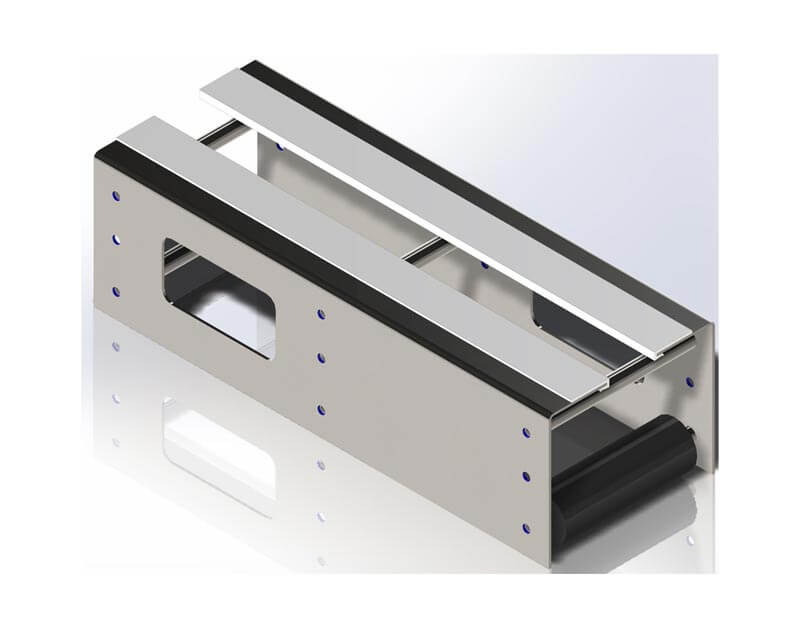

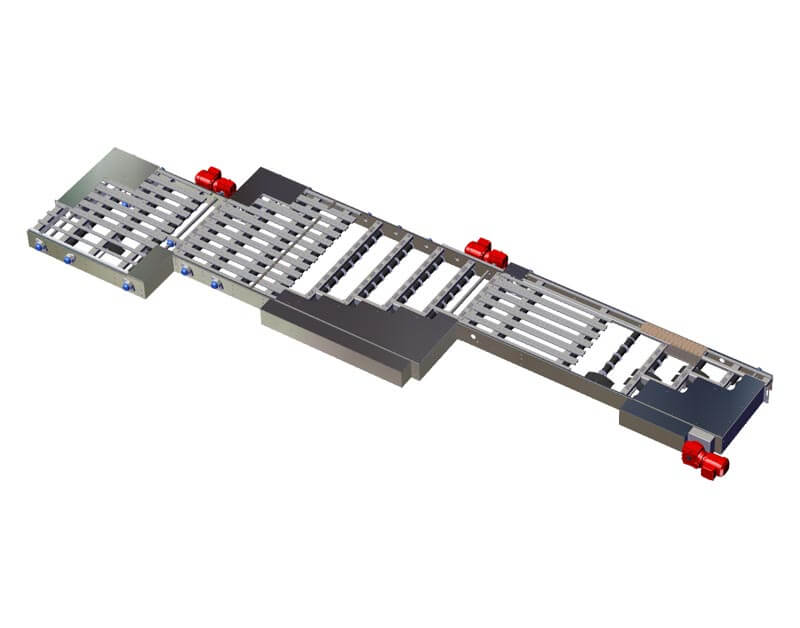

USDA style conveyors for the dairy, food, and beverage industries.

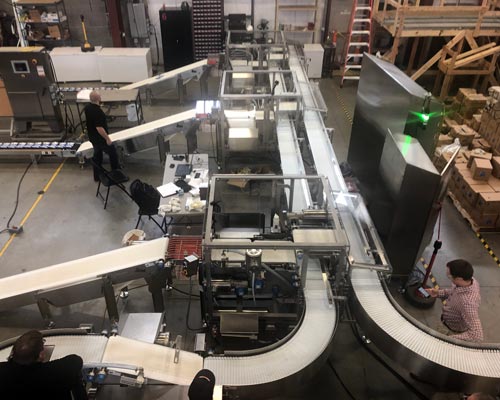

Many companies are faced with daunting tasks that are being completed by employees in a repetitive, strenuous, and expensive manner. However, similar businesses are now turning to conveyor systems as an effective solution for handling these types of tasks within their .

Our experts at Integrated Packaging Machinery provide conveyor system products and solutions that are unique to each business and their operations.

Benefits of Conveyor Systems

Conveyor systems are most commonly found in the manufacturing industry because of the large product loads these businesses produce and need to move or transport daily. Even though the benefits of a conveyor system are going to differ from business to business, some of the more general benefits of these systems include the following:

- Conveyors can move easily in multiple directions and from one elevation to another, which allows products and material to be moved effortlessly to different parts of the facility.

- Conveyors can eliminate manual tasks in the manufacturing process that can help a business save time and money on labor and materials, while also reducing error and improving efficiency.

- Conveyors provide endless opportunities to continually load and unload items over a long period of time throughout the manufacturing process.

- Conveyors decrease the likelihood of something breaking or being mishandled by allowing careful control of the speed at which materials move through the process.

One primary advantage of a conveyor system is that they can be effectively used to automate certain tasks in the manufacturing process as well as in the transportation of materials that are being completed manually. These manual tasks which are important in food industry conveyor systems include aspects of the process such as feeding, moving, loading and unloading of materials.

UPTIME IS THE ONLY TIME THAT MATTERS!

Types of Conveyor Systems

Since companies differ in their production process as well as their product line, there is no universally used type of conveyor system. Each conveyor that is designed and built by Integrated Packaging Machinery is unique to our client’s business and their operations. Below is a general list of the types of product and case conveyor systems available.

Why Choose IPM?

Integrated Packaging Machinery uses readily available parts and suppliers for components for constructing USDA-style conveyors. Our conveyor systems for the food, dairy and beverage industries are also designed with tool-less removable UHMW carry-way and return-way chain guides for easy removal and cleaning. IPM selects and maintains long-term relationships with suppliers in order to reduce costs and lead-times for our equipment. We strive to continually upgrade our products and solutions to ensure that we are exceeding our customer’s expectations.